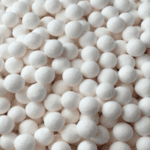

Activated alumina is a form of aluminum oxide (Al2O3) that is highly porous and exhibits a surface area significantly greater than that of typical aluminum oxide compounds. This property makes it exceptionally useful in a variety of industrial applications. Here, we will explore five key uses of activated alumina. Each application benefits from the unique attributes of activated alumina, such as its adsorption capabilities, physical robustness, and chemical stability.

Desiccants

One of the most common applications for activated alumina is as a desiccant. Due to its porous nature and large surface area, activated alumina can adsorb a significant amount of water vapor from the air. This makes it ideal for use in air dryers, where removing moisture is crucial for preventing corrosion and maintaining the efficacy of various systems. Activated alumina desiccants are widely used in compressed air and gas drying because of their ability to adsorb water under high-pressure conditions. Furthermore, the material can be regenerated by heating, making it a cost-effective option for continuous operations.

Claus Catalysts

Activated alumina also plays an essential role in the Claus process, which is a key method for converting hydrogen sulfide (H2S) into elemental sulfur. This process is vital for the natural gas and petroleum refining industries, where sulfur recovery is crucial for both economic and environmental reasons. Activated alumina serves as a catalyst in the Claus process, enabling the chemical reactions necessary to transform H2S and sulfur dioxide (SO2) into elemental sulfur. The high surface area and chemical stability of activated alumina make it an ideal material for facilitating these reactions. Its effectiveness in this role helps refineries meet regulatory standards for sulfur emissions while recovering valuable sulfur.

Deflourinator Catalyst

Activated alumina is highly effective as a defluorinator in hydrocarbon streams, playing a crucial role in refining processes where the removal of fluoride is essential. Fluoride contamination in hydrocarbon streams can lead to equipment corrosion and catalyst poisoning, thereby impacting the efficiency and longevity of refining systems. Activated alumina’s high surface area and robust adsorption capabilities allow it to capture and remove fluoride ions, ensuring the integrity and performance of refining operations. This makes it indispensable in the treatment of propane, butane, and alkylate streams, where maintaining low fluoride levels is critical for product quality and equipment maintenance.

Chloride Adsorbents

Activated alumina is also utilized as a chloride adsorbent in various industrial processes. Chlorides can cause significant corrosion issues in pipelines, reactors, and other equipment used in the petrochemical and refining industries. Activated alumina can adsorb chloride ions, thereby reducing their concentration and mitigating potential corrosion damage. This application is vital for maintaining the integrity of infrastructure and extending the lifespan of critical industrial equipment. By incorporating activated alumina as chloride adsorbents, industries can achieve higher efficiency and longevity in their operations.

COS Hydrolysis

Activated alumina is used in the hydrolysis of carbonyl sulfide (COS) to carbon dioxide (CO2) and hydrogen sulfide (H2S), which is an important reaction in gas purification processes. COS is a toxic compound that can be harmful to both human health and the environment. The hydrolysis process involves passing the gas stream over activated alumina, which acts as a catalyst to convert COS into less harmful substances. This application is particularly relevant in industries such as natural gas processing and refining, where COS is a common contaminant. By using activated alumina, these industries can improve the safety and environmental compliance of their operations.

In Summary

Activated alumina is an incredibly versatile material with multiple industrial applications. From serving as desiccants and catalysts to functioning as adsorbents and agents in hydrolysis, its unique properties make it indispensable in various sectors. The use of activated alumina in these processes not only enhances performance but also ensures durability and cost-effectiveness. Through its roles in moisture control, sulfur and chloride adsorption, fluoride removal, and gas purification, activated alumina continues to be a critical component in enhancing industrial efficiency and environmental compliance. As industries evolve and new challenges arise, the demand for high-performance materials like activated alumina will undoubtedly persist.

If your business operations require quality activated alumina, contact us to learn more about our ACTIMAX® activated alumina. In addition, we offer a comprehensive portfolio of products designed to support these applications. At M Chemical, our team is ready to help you get the superior quality products you need, when and where you need them.